The Advanced Materials & Sustainability Program within RDTS focuses on the science and engineering of materials, chemistries, and construction techniques that unlock higher performance with lower environmental footprint across the well and asset life cycle. Advanced materials and processes can positively influence environmental sustainability in several powerful ways.

- Dematerialization and substitution.

- Manufacturing and transportation efficiency.

- Lifetime extension of critical components and systems.

- Recycle and reuse of materials and fluids.

- Unlocking new, previously untapped resources.

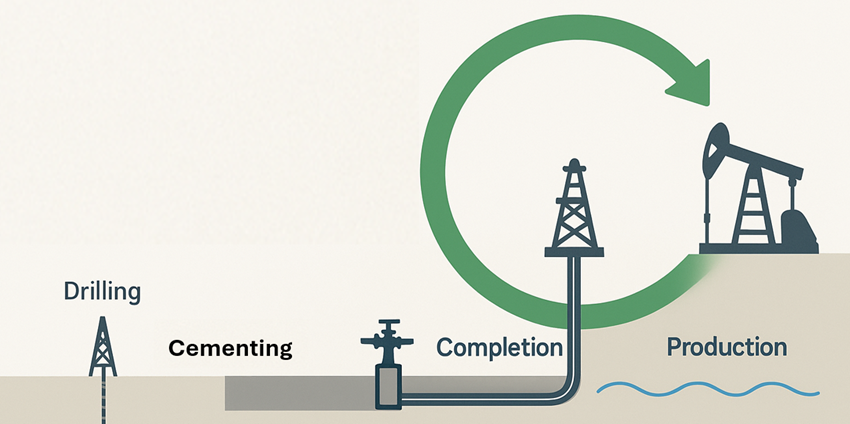

In essence, advanced materials act as enablers of sustainable technologies—they reduce the environmental footprint of industries, enhance resource efficiency, and open new pathways toward a low-carbon future. Both metallic and non-metallic materials play significant roles at different stages of hydrocarbon extraction, starting from drilling and cementing through completion and production. Members are encouraged to share their research and technologies in advanced materials and processes toward higher performance and reliability, lower carbon footprint, and full life-cycle considerations.

Low-Carbon Cements

Well Integrity & Zonal Isolation

Corrosion & Materials Selection

Geothermal & High-Temperature Service

CCUS, Hydrogen & New Fluids

Life-Cycle & Circularity

Program goal: Foster open discussion on R&D innovations, emerging technologies, and processes in the well construction domains.

Program focus domains:

- Drilling.

- Cementing.

- Completion (and interfaces with production).

Short-term plans (2025–2026):

- Engage young professionals (YPs) in shaping and delivering the program.

- Host quarterly webinars by subject-matter experts.

Long-term plans:

- Develop regional workshops focused on advanced materials and sustainability.

- Publish technical newsletters to highlight new developments and case studies.

- Encourage adoption of new technologies through collaboration across operators, service companies, and academia.

Illustrative figures from the AMS program overview deck. Replace the image URLs below after uploading the slide graphics to the RDTS file library on SPE Connect.

Highlight Low-Carbon Cement

LC³ / Slag & Alternative Binder Systems

Summarize how low-clinker cement systems are being evaluated or deployed in well construction: lab performance, CO₂ footprint reduction, and compatibility with conventional cementing workflows.

- Key performance metrics (compressive strength, permeability, durability).

- Field trials and lessons learned.

- Outstanding R&D questions.

Highlight Geothermal & CCUS

High-Temperature & CO₂-Resistant Materials

Use this panel for materials that enable long-term integrity in geothermal and CO₂ injection wells: elastomers, steels, coatings, and zonal isolation systems.

- Thermochemical loads and design envelopes.

- Qualification protocols and standard gaps.

- Collaboration needs across operators and suppliers.

You can duplicate these cards to add additional technology themes (e.g. corrosion-resistant alloys, nano-materials, bio-based polymers, circular materials, etc.).

JPT Feature · RDTS / AMS Theme

Low-Carbon Cement & Well Construction for Net-Zero

Use this card to link to an SPE JPT article or technical paper summarizing the state of the art in low-carbon well construction materials.

SPE Paper / Conference Proceedings

Materials for CO₂ & Hydrogen Service

Recommended set of SPE papers on corrosion, embrittlement, and integrity management for CO₂ and hydrogen storage and transport.

- Paper 1 – short one-line description.

- Paper 2 – short one-line description.

External Report / Standard

Guidelines & Standards on Sustainable Materials

Link to key industry guidelines (API/ISO/CSA, etc.) or cross-industry reports on material sustainability, life-cycle assessment, and circularity.

Tip: As the reading list grows, consider grouping items by theme (cements, CCUS, geothermal, circular materials, standards) or by level (introductory vs. advanced).